Courses

Keep your staff up to date with training courses from the experts at SHERMCO.

Digital Chalk General Technical Training In-person Safety Training Virtual

Showing 1–16 of 45 results

-

2025 National Electrical Code (Virtual)

This course is designed to give new or experienced users of the National Electrical Code (NFPA70) practical experience in applying…

-

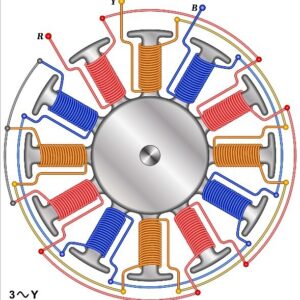

AC Motor Theory

*Need Digital Chalk account to sign up, click to create account.

AC motors are widely used to drive machinery for a wide variety of applications. To understand how these motors operate,…

$95.00 -

AC Motor Types

*Need Digital Chalk account to sign up, click to create account.

Various types of AC motors are used for specific applications. By matching the type of motor to the appropriate application,…

$95.00 -

Arc Flash Mitigation Techniques

*Need Digital Chalk account to sign up, click to create account.

An Arc Flash is the passage of substantial electrical current through ionized air. The result is a violent release of…

$95.00 -

Basic Electrical Fundamentals

Whether you are new to the industry or are taking on additional responsibilities for electrical maintenance, a solid knowledge of…

-

Basic Electrical Technical Skills

A 3-day companion course to Basic Electrical Fundamentals, this course features a detailed, hands-on training regimen on the use of…

-

Battery Maintenance and Testing

*Need Digital Chalk account to sign up, click to create account.

This training module will introduce students to stationary batteries, and the maintenance & testing they require. The student will learn…

$95.00 -

Cable Splicing and Terminating

*Need Digital Chalk account to sign up, click to create account.

A properly installed splice or termination can have a life expectancy of 25 years or more, and a poorly installed…

$95.00 -

Circuit Breaker Testing and Maintenance

*Need Digital Chalk account to sign up, click to create account.

Circuit breakers are used in nearly all electrical systems — from residential dwellings to electric utility facilities. We rely on…

$95.00 -

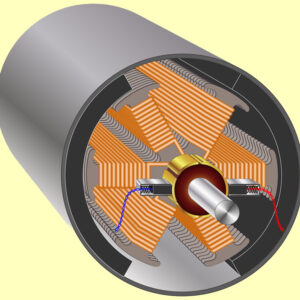

DC Motors

*Need Digital Chalk account to sign up, click to create account.

In this training session, we will explore DC motors. This training module is ideal for both new and experienced electricians…

$95.00 -

DigitalChalk JumpStart Course 2023

*Need Digital Chalk account to sign up, click to create account.

-

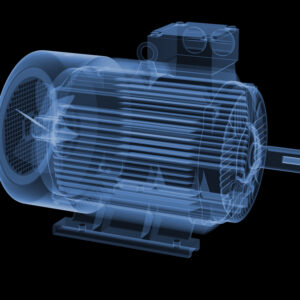

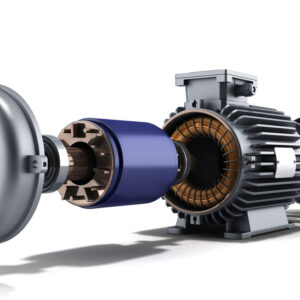

Electric Motors – Construction and Failure Mechanisms

*Need Digital Chalk account to sign up, click to create account.

Motor-driven equipment accounts for 64% of the electricity consumed in the U.S. industrial and commercial sectors. All industrial or commercial…

$95.00 -

Electrical Power Distribution Systems

*Need Digital Chalk account to sign up, click to create account.

The primary function of the electrical power distribution system in a building or facility is to receive power at one…

$95.00 -

Electrical Safety for Managers (Virtual)

As is often the case, supervisors, managers, and engineers who are responsible for plant maintenance are not actually the individuals…

-

Electrical Safety for Non-Electrical Personnel (Virtual)

Virtually every worker on an industrial or commercial job site works with or uses electrically-powered equipment. Most of these workers…

-

Electrical Safety for Qualified Electrical Workers

Designed for all maintenance and testing personnel who work on or near electrical equipment. This seminar meets and exceeds the…

$850.00